央视新闻 2021-10-20

China's independent development of the world's largest thrust and engineering application of the integrated solid rocket engine in the fourth institute of China Aerospace Science and Technology Corporation successfully test run.

With a diameter of 3.5 meters and a thrust of 500 tons, the engine adopts a number of advanced technologies, such as high-performance fiber composite shell, high-loading integral cast-in-shape combustion chamber and super-size nozzle, and its comprehensive performance reaches the world's leading level. The success of the test marks a significant improvement in China's solid launch capability, provides more power options for the development of China's launch vehicle spectrum, and is of great significance for promoting the development of large and heavy launch vehicle technology in the future.

Carrying development, power first. As early as in the 11th Five-Year Plan period, Chinese spaceflight personnel made preparations for the future, aiming at the frontier of space development in the world and the technical demand of China's launch vehicles for high-performance solid rocket engines with large thrust, and based on the two technical routes of "integral" and "segment-type", they carried out preliminary research on large solid rocket engines.

In 2009, China successfully developed an integrated solid rocket engine with a diameter of 2 meters and a thrust of 120 tons, which was the largest in China at that time. It directly promoted the project development of the Long March 11, the first all-solid carrier rocket in China's Long March series, and became an important milestone in China's solid power toward space launch vehicles.

Long March 11 solid carrier rocket

In 2019, in order to further enhance the solid carrier capacity and the competitiveness of the commercial space market, China independently developed an integrated solid engine with a diameter of 2.6 meters and a thrust of 200 tons. While further improving the solid power carrier capacity of China's space, it also promoted the project development of the Dragon iii commercial space carrier rocket.

Rendering of the Dragon 3 commercial Space Launch vehicle

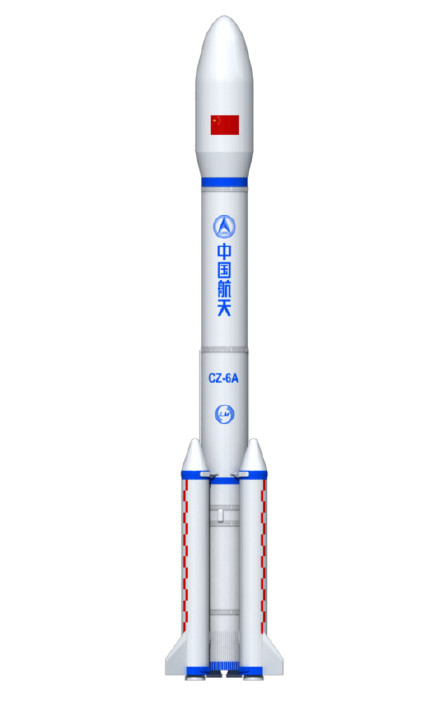

With the development of integral solid engine, the step of segmental engine has never stopped. In 2016, with the continuous maturity of segway docking technology, China successfully carried out a ground thermal test of a 2-meter diameter segway engine on the basis of a 120-ton integrated high-thrust engine. The engine combustion chamber was formed by the docking of two comparttions with thrust of 120 tons, which successfully verified the segway docking technology of solid engines. It also directly promoted the project development of China's first bound solid booster carrier rocket, CZ-6A.

Rendering of THE CZ-6A launch vehicle

After that, the 3-meter and 3.2-meter segway engines were successfully tested one after another, and the segway docking technology continued to develop and the technology maturity increased rapidly. In particular, on December 30, 2020, the successful ground thermal test of 3.2-meter-3-stage Large solid rocket Engine for civil aerospace, a self-developed solid stage booster with the largest diameter, the largest charge and the longest working time, has greatly improved the technology and capability of China's large solid rocket engine.

3.2 m 3 stage large solid rocket engine

Currently, based on the 500-ton thrust monolithic solid engine, the fourth Institute of Aerospace Science and Technology Corporation has been carrying out research on the 3.5-meter diameter segment-level engine. The engine is divided into five sections, and the maximum thrust will reach more than 1,000 tons, which can be applied to the solid boosters of large and heavy carrier rockets. In order to meet China's space equipment, manned lunar landing, deep space exploration and other space activities for the different development needs of carrier vehicles, for the establishment of domestic solid and liquid carrier rockets complement each other, and improve the space transport system to provide more powerful dynamic support.